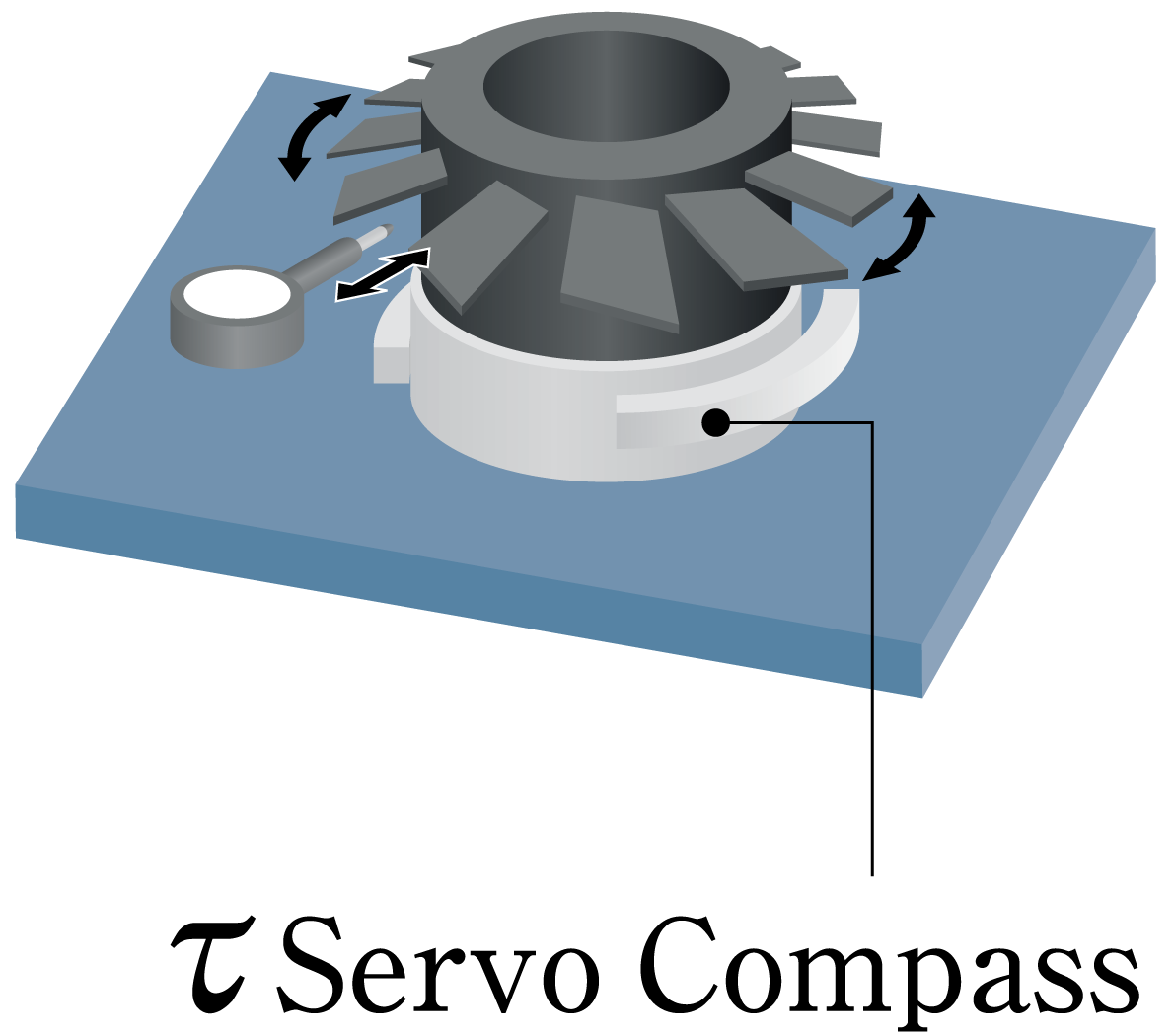

The τServo Compass arc type linear servo motor was introduced to the blade shape measuring instrument for aircraft engines. Replacing the existing American-made DD motor improved performance and maintainability.

The customer uses a foreign-made motor in its existing aircraft parts measuring instrument but has a maintenance problem since the local subsidiary of the manufacture of this motor has withdrawn from the Japanese market.

Since the measuring instrument was huge, we created a machine with the τServo Compass built in it, through a tie-up with an instrument manufacturer. This improved the measurement performance and support service.

[Problem] The support system for the foreign-made motor built in an aircraft parts measuring instrument will be discontinued.

The customer used American-made direct drive motor and air bearing in the instrument for measuring the shape processing accuracy of jet engine blades. Since this manufacturer’s local subsidiary has withdrawn from the Japanese market, its support system will be discontinued and requests for maintenance will no longer be accepted. So, the customer was considering a switch to a domestic manufacturer capable of offering motors that meet their requirements such as size and load durability. The customer upgraded the instrument because it would likely be one of their main products and put on display at trade shows.

[Proposal/solution] Design and develop a massive instrument with the τServo Compass through a tie-up with an instrument manufacturer

When you deal with an aircraft parts measuring instrument, you’ll face the problem of size. So, we decided to tie up with an instrument manufacturer that we have done business with for a long time. We delivered the τServo Compass arc type linear servo motor. First of all, the motor has to be thin and large because it will be embedded at the base of the instrument. It also must be capable of enduring a large load. In addition, since the motor has a large hollow in the center, there is a shape-related condition requiring that it allow an object, such as a part being measured, to be placed in the central part. The motor meets these requirements, and its characteristics, such as speed and rotation speed, match the customer’s needs. That’s why the customer chose our motor. Replacing the existing motor with ours has not only made a full support service available but increased measurement performance as well. Now, the customer can rest assured when providing users with their products.

Key points in adopting our proposal

- Full support that can be provided only by a domestic manufacturer

- Thin, space-saving motor

- Arc type linear servo motor with a large hollow diameter

Related products

τServo compass