We offer a wide range of customization options that other companies cannot accommodate.

Customized products account for about 80% of our domestic sales, and we take pride in being the industry leaders in terms of the ability to accommodate customer needs. Many customers whose requests have been turned down by other companies contact us, asking if we can meet their needs. Leveraging our superb technological capabilities and the know-how of servo motors that we have amassed over the years, we strive to solve problems of these customers.

Customization examples

Here are some of the main customization options and special specifications we offer. There may be additional possibilities, so please feel free to contact us for more details.

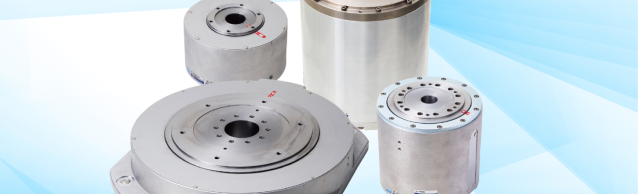

Direct drive motor customization examples

Main customization options and special specifications

- Improved speed stability

- Fretting prevention specification

(Measures to extend bearing life in environments where very small angle, continuous reciprocating operation and regular rotation operation cannot be performed) - Built-in motors

(Built-in rotors and stators for air bearings and ball bearing spindles; or supply of only rotors and stators) - Vacuum support

- Improved positioning accuracy and rotation accuracy

- Improved torque accuracy

- Improved flatness and parallelism

- Increased motor speed and torque

- Dust-proof specification

- Material and surface finish changes

- Expansion of hollow hole diameter, modification of mounting shape

- Connector and cable changes

Linear servo motor customization examples

Main customization options and special specifications

- Increased thrust and speed

- Water cooling and air cooling support

- Vacuum support

- Construction of arc-type linear stages (Servo Compass stages)

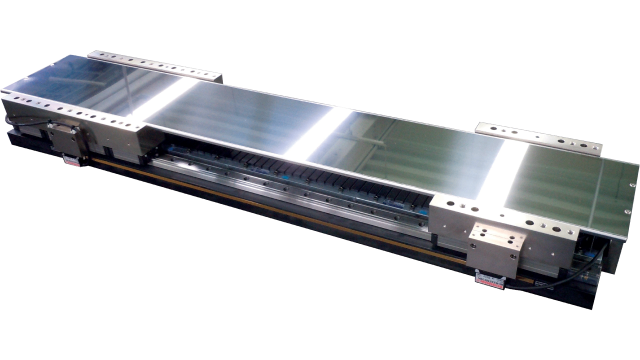

Linear stage customization examples

Semi-custom-made stages

Based on standard linear stages, the specifications of the following items can be changed.

- Stroke

- Linear servo motor

- Linear scale

- Non-standard θ axis

- Linear guide

- Zero point position

- Table/base mounting holes

- Surface treatment

- Material

- Top table size

- Cablevoyor

- Improvement of mechanical and dynamic accuracy

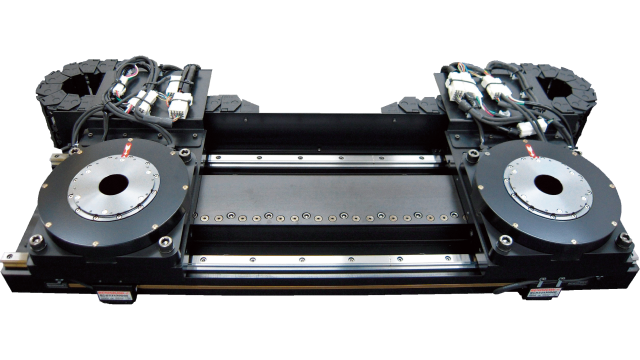

Full custom-made stage

We support special specification stages such as multi-head stages, long-stroke stages, and stages with frames.

[Xθ2 head type linear stage]

・Equipped with high-accuracy direct drive

・For glass tube bending equipment

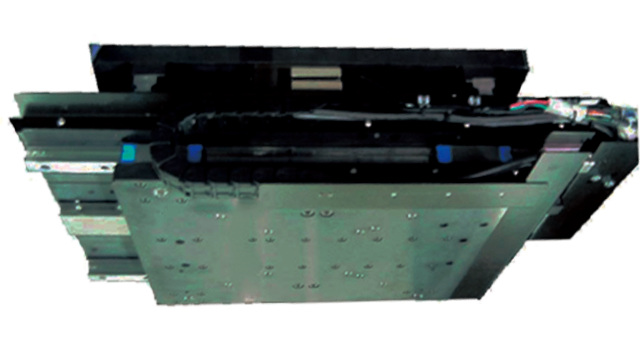

[X2 head type liner stage]

・With stainless steel cover

・For LCD panel inspection

[XY linear stage]

・Mountable upside down

・Speed variation ±0.2%

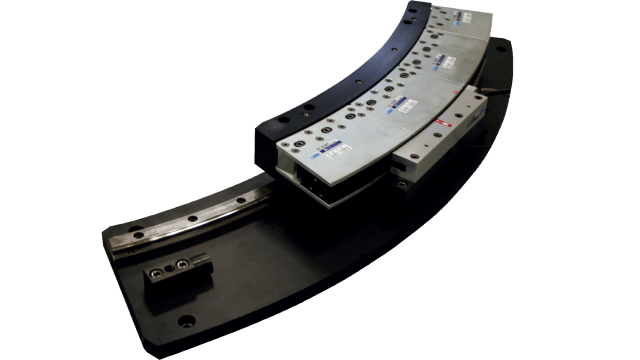

[Servo Compass stage]

・For alignment applications

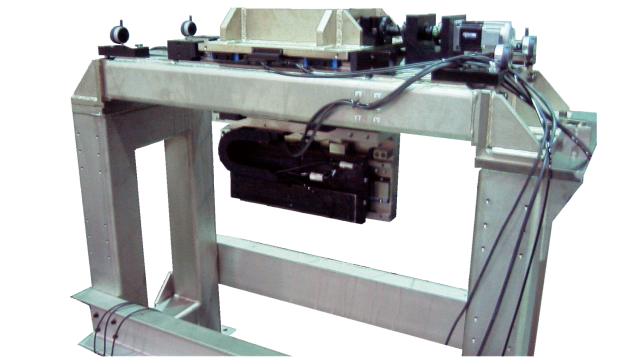

[With frame]

[X3 head]

[Coil movable & magnet movable]

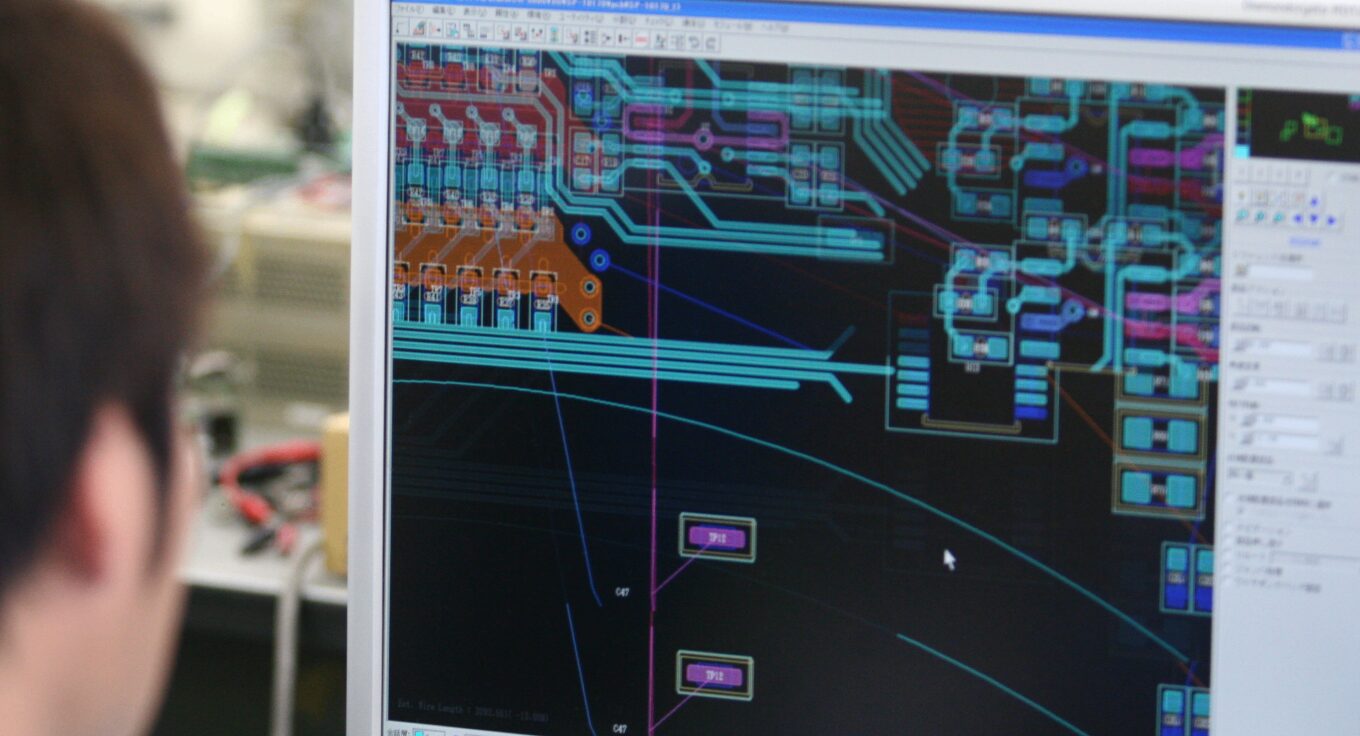

Servo driver customization examples

Semi-custom-made servo driver

- Function and performance improvements through partial changes to software and hardware of the servo driver

Full custom-made servo driver

- Dedicated servo drivers for special motors

- Development of DC-powered servo drivers