The problems with the profilometer, such as rotation speed stability and cogging reduction, have been solved by introducing a coreless built-in motor, leading to increased measurement accuracy.

The customer had the problem of low speed stability with its parts measuring instrument that used an AC servo motor and gear.

Introducing a coreless built-in motor provided speed stability and smooth operation, leading to increased measurement accuracy.

[Problem] The customer wanted to stabilize the rotation speed of a parts measuring instrument and increase measurement accuracy.

A measuring instrument manufacturer needed to develop an auto parts measuring instrument with higher accuracy in response to requests for higher accuracy from automakers, users of their measuring instrument. This instrument measures the roundness and surface profile of a part by rotating the part slowly using a motor, and a change in behavior during the inspection decreases its measurement accuracy. The manufacturer told us that they wanted to stabilize the rotation speed to address this problem. The existing instrument had a mechanism made up of an AC servo motor and a gear, and it was necessary to replace the motor to solve the problems facing the manufacturer. They said they considered using our direct drive motor as an option.

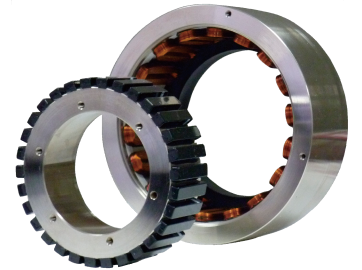

[Proposal/solution] Change to a coreless DD motor to stabilize the rotation speed of the measuring instrument and make it cogging-less high-accuracy machine.

We proposed changing from an AC servo motor to a direct drive motor. But the core direct drive motor the manufacturer first adopted did not make a significant improvement since it had a strong magnetic force suction, resulting in cogging. So, we proposed using a coreless direct drive motor instead. This stabilized the rotation speed while achieving cogging-less, smooth motion. We also replaced the tip (pick) of the measuring instrument with a laser. The customer says that the machine is well received by users as a high-accuracy non-contact measuring instrument that does not damage parts.

Key points in adopting our proposal

- Rotation speed stabilized by changing from an AC servo motor to a coreless DD motor

- Introduction of a coreless DD motor has made the measuring instrument cogging-less

- Customer-centered full support

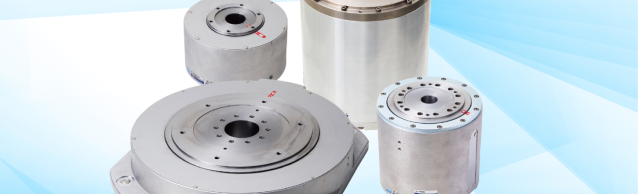

Related products

Built-in motor