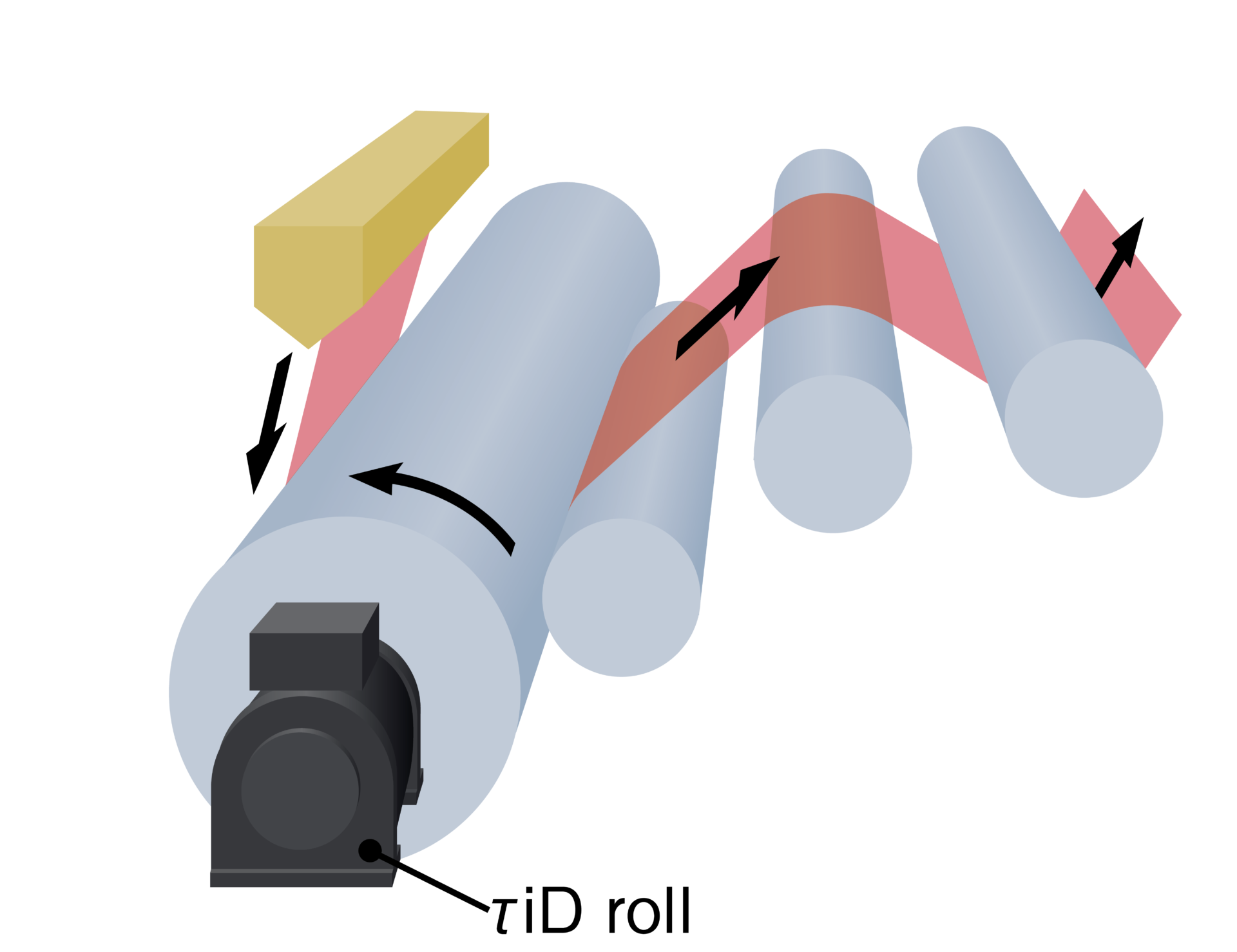

Replacing the conventional speed reducer-equipped motor with the cylinder-type direct drive motor τiD roll made film production equipment less prone to fail and more accurate.

The customer uses a rolling contact-type speed reducer because of the need to drive a large roll smoothly at a large torque, but they have suffered from occasional failures.

Changing to the τiD roll capable of high rotation accuracy and large torque output eliminated the need for the problematic speed reducer, enabling long-term maintenance-free operation.

[Problem] The customer uses a rolling contact-type speed reducer because of the need to drive a large roll smoothly at a large torque, but they have suffered from occasional failures.

The problem with the customer’s existing film production equipment is the stoppage of the production line due to an abrupt failure of the speed reducer. Every time a failure occurs, the production line needs to be stopped for repair or replacement, inevitably leading to decreased yields. The motor is required to have high rotation accuracy and large torque. So, when selecting the manufacturer of the direct drive motor that would replace the existing motor, the customer called for the ability to meet customization needs flexibly.

[Proposal/solution] Replacing the existing motor with the τiD roll achieved maintenance-free operation and improved productivity.

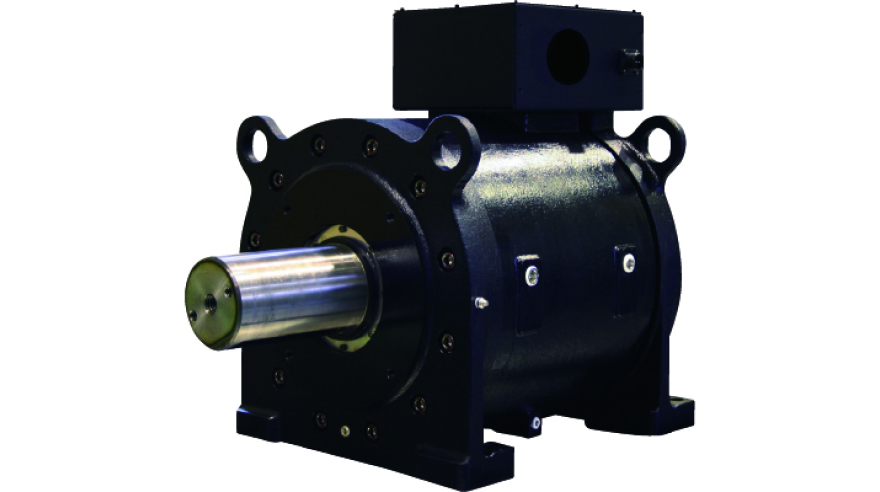

We proposed the introduction of the τiD roll, a direct drive motor that does not require the use of a speed reducer. With the speed reducer gone, which was the source of failure, the customer is no longer forced to stop the production line, thus making it almost maintenance-free. An increased line operation rate has improved productivity, bringing an improvement in yields among other benefits. Since the customer requested that the equipment have high rotation accuracy and large torque, we customized the motor to reduce speed ripples and support large torque.

Key points in adopting our proposal

- Maintenance-free operation enabled because there is no need for speed reducers and other intermediate mechanisms

- Stable control supported by high rotation accuracy and large torque

- Customization to meet customer requirements

Related products

τiD roll water cooling-type iD Series