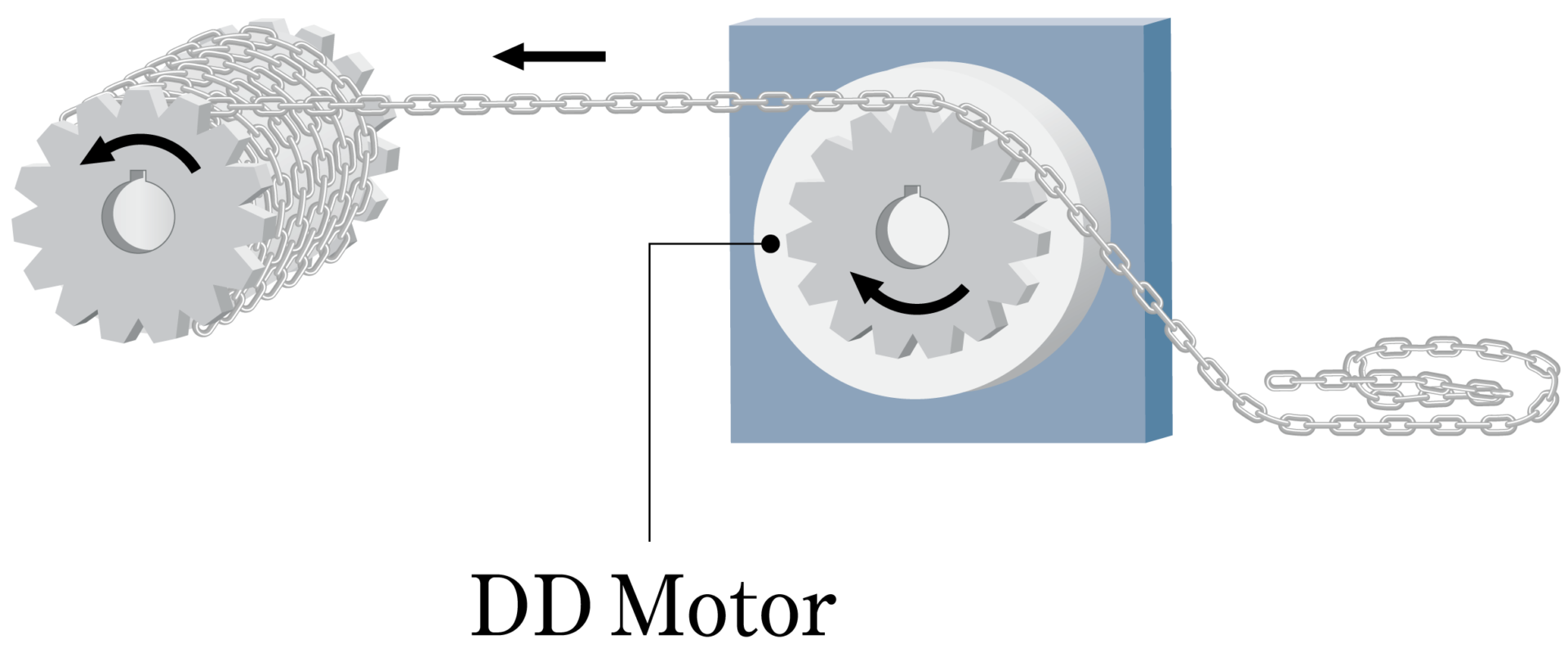

Using a direct drive motor to maintain tension provides space saving and highly accurate, stable control.

The customer considered using a back tension axis to prevent the chain from slacking when winding. Out of considerations for space and accuracy, the customer wanted a simple mechanism.

Replacing the back tension axis with a DD motor eliminated the need for intermediate mechanisms such as a speed reducer. This provided space saving, higher accuracy, and greater control, resulting in a simple mechanism.

[Problem] The customer wants to save space by adopting a simple mechanism for the back tension axis of a chain winding machine.

An end user asked the customer about the back tension axis of an automobile chain winding machine. The end user considered building the machine with an AC servo motor and a speed reducer. But an AC servo motor would have multiple intermediate mechanisms. That was expected to make the machine bigger and adversely affect work efficiency due to backlash and other factors.

[Proposal/solution] Introduce a DD motor to build a simple, space-saving machine without intermediate mechanisms.

While a direct drive motor is generally used for high-accuracy, high-speed indexing, it also excels in torque control and speed control for tension maintenance. Moreover, since the motor does not require any intermediate mechanism, it provides higher accuracy, greater control, and space saving. We proposed the use of a direct drive motor to the customer for the reasons described below, and the customer considered our proposal and decided to use the motor.

① The motor length can be reduced.

When an AC servo motor equipped with a speed reducer is about 1 meter long, the length can be reduced to about 1/5 if a direct drive motor is used. This significantly reduces the amount of protrusion from the machine.

② Resolution of speed reducer problems

A speed reducer has a number of uncertain factors such as oil leak, torque loss, backlash, and angular speed fluctuation. These problems can be resolved by using a direct drive motor.

The customer introduced a direct drive motor for the first time. But we had thorough discussions in advance, and the customer is now using the motor without a hitch.

Key points in adopting our proposal

- Space-saving design, high accuracy, and great control

- Quick delivery of the motor selected from a rich lineup of standard models

- Reliable support service

Related products

τDISC ND-s Series