The foreign-made vacuum rotation mechanism used by the customer had some problems. We proposed using our built-in direct drive motor in combination with the customer’s encoder, which enabled greater control and stable procurement.

The customer wanted to replace a foreign-made vacuum rotation mechanism with a domestically produced one and, due to many technical constraints, was looking for a domestic manufacturer capable of solving the problems.

We proposed a customized product created using our existing technology. The product was delivered, with a built-in direct drive motor and the customer’s encoder built into a magnetic fluid sealing unit.

[Problem] The customer wanted to replace a foreign-made vacuum rotation mechanism of semiconductor front end processing equipment with a domestically produced one, but it would be very difficult technically.

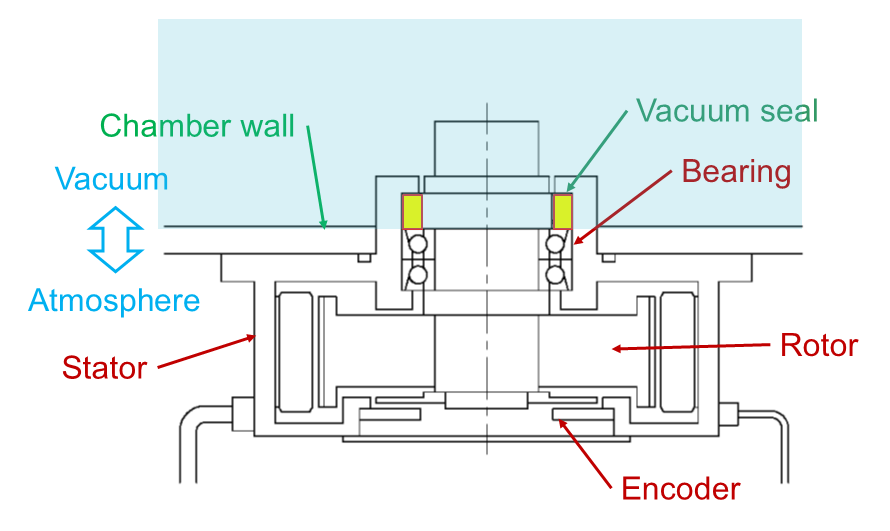

The foreign-made vacuum rotation mechanism that the customer used in the semiconductor front end processing equipment provided vacuum only to the rotating body sandwiching the partition wall. This mechanism had the problem of poor control over vibration and others as well as the procurement problem. While the customer tried to solve the problems by replacing it with a product of a domestic manufacturer, the mechanism had many technical constraints. This made it difficult for the customer to find a domestic manufacturer capable of providing fine-tuned customization.

[Proposal/solution] We provided a vacuum DD motor as a unit, which enabled greater control and stable procurement.

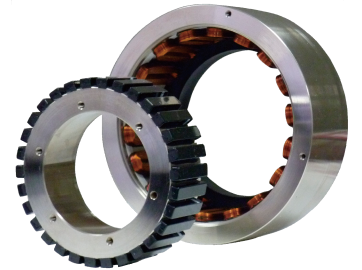

Reproducing the same operating principle as that of the existing foreign-made vacuum rotation mechanism would have an enormous development impact on us. So, we proposed introducing the built-in direct drive motor developed using our existing technology and using it in combination with the customer’s encoder. This proposal was accepted. But it turned out that, if the customer assembled the motor and encoder, the manufacturing quality could not be guaranteed since they were not familiar with the task.

So, we had the customer supply a magnetic fluid sealing unit to us and assembled the built-in direct drive motor and the customer’s encoder in our plant. This solved the problem of the manufacturing quality. Moreover, it achieved greater control due to the difference in the operating principle and secured stable procurement, something possible only with a domestic manufacturer.

Key points in adopting our proposal

- Flexible system for fine-tuned support

- Flexible customization using the customer’s encoder

- Vacuum technology fostered over the years

Related products

Built-in DD motor

Customized product