FAQ

FAQ

Basic product information

The price of a product differs depending on the specifications, quantity, purchase conditions, etc. Contact our Overseas Sales Dept. or your local sales department directly, or contact us through the Contact page of this website.

Some products are made according to plan, and some are made to order. The delivery period differs from product to product. Contact our sales department directly, or contact us through the Contact page of this website.

τDISC

This is a rotary direct drive motor that is hollow. Equipped with a high-resolution encoder, the product can generate a large torque at low speed (typically 180 rpm or less) while being compact in shape. Its multi-pole structure enables smooth rotation even in an extremely low speed range. The rated torque ranges from 1.6 N∙m to 2000 N∙m. The lineup consists of more than 50 models.

τiD roll

While being compact, this cylinder-type direct drive motor offers large torques (rated torque: 150 N∙m to 7500 N∙m). It provides high accuracy, high response, and cleanliness to general industrial machines that are driven by the conventional geared AC servo motor, such as injection molders and servo presses.

τLinear

This is a straight line motion-type linear motor. There are two types: the core type with an iron core in the coil and the coreless type without an iron core. The coreless type without an iron core in particular can generate high thrust while being more compact and thinner than competitors’ products.

τServo Compass

This is a linear motor that produces an arc motion, which is best suited to positioning in a limited motion range. The maximum motion range is 360 degrees. With the motor and encoder placed in a radial direction from the center of rotation, the motor can generate a large torque, despite its low output, enabling ultra high-accuracy positioning. Since there is no drive mechanism near the center of rotation, the motor can have a large hollow, providing a significantly high level of flexibility in equipment design.

τLinear Stage

A linear stage is a stack-type table mechanism that provides flexible motion and positioning functions when used in combination with an actuator that can freely move in each of the X (horizontal) axis, Y (horizontal) axis, θ (rotation) axis, and Z (vertical) axis. Combining this linear stage with any of the direct drive motors mentioned above makes for a lightweight, compact, highly rigid product with a simple structure that takes advantage of the benefits of the direct drive. Such a product enables positioning with submicron accuracy and increased takt time performance.

Stage block

This cost-oriented linear stage is ideal for transport applications. By combining the stage block with a direct drive motor, it is easy to build X, XY, Xθ, and XYθ stages with various strokes. The lineup also includes long-stroke models best suited for use in high-speed, long-distance transport.

We have a showroom in our Sakura Office in Chiba Prefecture. Portable demo machines are also available. If you want to try these demo machines on your premises, contact our sales department directly or contact us through the Contact page of this website.

We accommodate customization requests, although not for all our products. See here for examples of customized products.

We have the τDISC ND-s Series in our product lineup.

Yes. For details, see Built-in motor.

Our product lineup includes scale-less stage blocks that do not use a linear scale, as well as stage blocks that support long strokes.

The following networks support servo drivers.

▼ VPH Series

SSCNET III/H (* linear servo motors not supported), EtherCAT, MECHATROLINK-III, CC-Link

How to select and purchase a product

Please inform us of your use conditions, and we will be happy to select a motor for you. To make a selection request, go to the Ask us to select a product for you page and download the required specification sheet. For the τDISC ND-s, ND-s HS, and DD-s Series direct drive motors, you can download the motor selection calculation tool.

Contact the sales departments listed below directly, contact us through the Contact page of this website.

South Korea

Nikki Denso International Korea Co.,Ltd

China

Taiwan

Singapore

Malaysia

Thailand

Vietnam

CKD Vietnam Engineering Co.,Ltd.

Indonesia

India

Europe

USA

Mexico

CKD MEXICO, S. de R.L. de C.V.

Areas other than the above

CKD NIKKI DENSO Overseas Sales Dept.

You can buy our products from our sales department serving your area. You can also buy them from a trading company. We have no dealerships. Contact our sales department directly or contact us through the Contact page of this website. Shown below are the sales departments of the respective areas from which you can buy our products.

* The departments are closed on Saturdays, Sundays, and national holidays, as well as during summer holidays and year-end and New Year holidays.

East Japan Sales Dept.

Covered areas

Hokkaido, Aomori, Iwate, Akita, Miyagi, Yamagata, Fukushima, Gunma, Ibaraki, Tochigi, Saitama, Chiba, Tokyo, Kanagawa, Niigata, Nagano, Yamanashi

Chubu Japan Sales Dept.

Covered areas

Aichi, Gifu, Toyama, Ishikawa, Fukui, Mie, Shizuoka

West Japan Sales Dept.

Covered areas

Shiga, Kyoto, Nara, Osaka, Wakayama, Hyogo, Tottori, Okayama, Shimane, Hiroshima, Yamaguchi, Kagawa, Tokushima, Ehime, Kochi, Fukuoka, Saga, Nagasaki, Oita, Miyazaki, Kumamoto, Kagoshima, Okinawa

Technical details

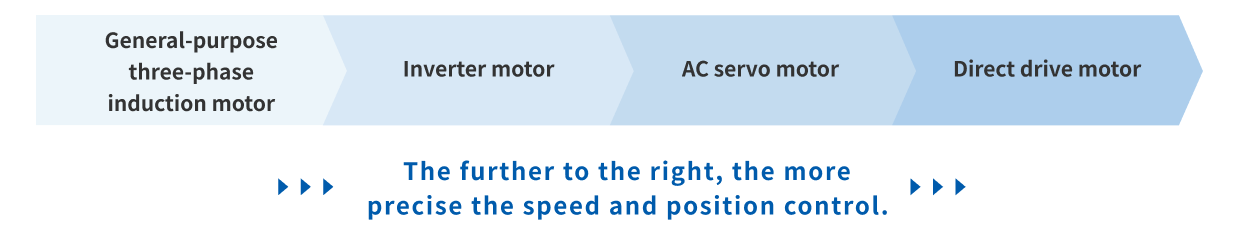

Generally, a direct drive motor has the benefits mentioned below. For information about the benefits of our products, see Features of the NIKKI direct drive motors.

Major benefits of the direct drive

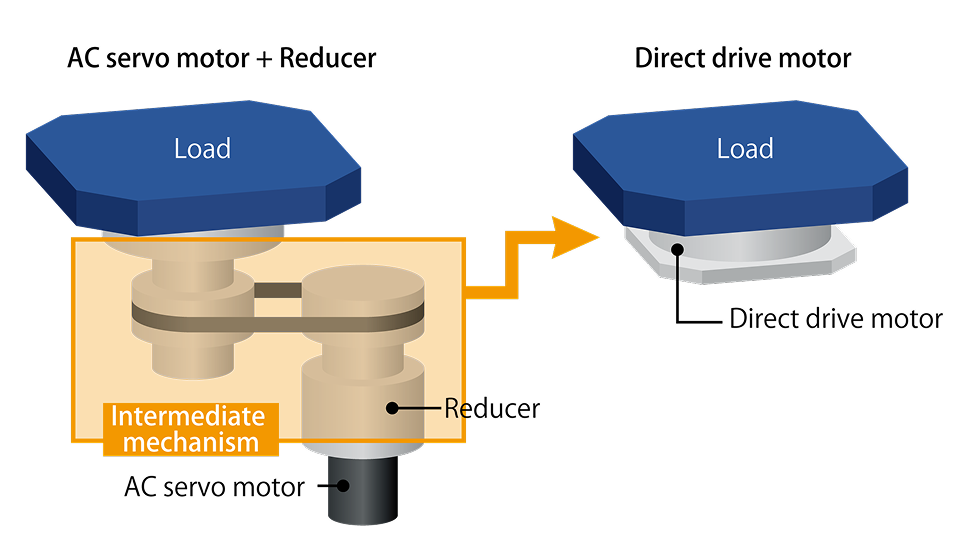

Improvement in mechanical performance

The omission of the intermediate mechanism makes it possible to increase the rigidity of the driving system and the mechanical resonance point, allowing the control characteristics of the servo motor to be reflected directly in the equipment. This substantially improves the mechanical performance, such as response performance, speed stability, and positioning accuracy, leading to higher quality and higher productivity among other things.

Space saving

The omission of the intermediate mechanism helps make the machine more compact and provides greater design flexibility.

Improvement in environmental performance

The omission of the intermediate mechanism reduces mechanical noise. There is no powder dust generated as the intermediate mechanism wears out, which leads to a cleaner environment. When you switch from a hydraulic drive to an electric drive, there will no longer be no oil leak or other similar problem, enhancing environmental friendliness and safety.

Less maintenance work

There is no need to replace the intermediate mechanism due to breakage, adjustment, wear, or the end of life.

Energy saving

Since there is no energy lost in the intermediate mechanism, the drive can be operated more efficiently, leading to energy saving.

The general-purpose AC servo motor generates a large torque effectively using an intermediate mechanism (speed reducer, belt, chain, etc.). A direct drive motor is a motor directly connected to the load (driven body) to transmit power or motion. There is no intermediate mechanism between the motor and driven body, which makes the power transmission system more rigid and enables backlash-less, high-speed accurate driving. For details, see Basic knowledge of the direct drive motor

Direct drive motors are used mainly in manufacturing, processing, and transport machines for semiconductors, liquid crystal substrates, and electronic components, as well as in printers, testers, medical equipment, and molding machines. For details, see Usage examples of the direct drive motor. Direct drive motors can be used in all types of equipment that require the performance characteristics mentioned below.

Higher equipment performance

Higher accuracy, shorter takt time, and higher precision are achieved.

Improvement in the equipment’s environmental performance

The equipment is quieter, more compact, and maintenance-free.

⇒ Ideal for switching from hydraulic control to electric control

⇒ Ideal for replacing the powder brake

A linear stage is a table mechanism equipped with a linear servo motor. Since it has no intermediate mechanism, the linear stage saves space and achieves excellent speed stability and high-accuracy positioning, compared to conventional transport mechanisms (ball screw, rack and pinion, belt, etc.).

Generally, a liner stage has the benefits mentioned below. For information about the benefits of our products, see Features of NIKKI linear stages.

Major benefits of the linear stage

Improvement in mechanical performance

The omission of the intermediate mechanism makes it possible to increase the rigidity of the driving system and the mechanical resonance point, allowing the control characteristics of the servo motor to be reflected directly in the equipment. This substantially improves the mechanical performance, such as response performance, speed stability, and positioning accuracy, leading to higher quality and higher productivity among other things.

Space saving

The omission of the intermediate mechanism helps make the machine more compact and provides greater design flexibility. A linear stage with multiple heads can make the mechanism much simpler.

Improvement in environmental performance

The omission of the intermediate mechanism reduces mechanical noise. There is no powder dust generated as the intermediate mechanism wears out, which leads to a cleaner environment. When you switch from a hydraulic drive to an electric drive, there will no longer be no oil leak or other similar problem, enhancing environmental friendliness and safety.

Less maintenance work

There is no need to replace the intermediate mechanism due to breakage, adjustment, wear, or the end of life.

Long-distance drive

High-speed motion over a long distance is possible because there is no deflection due to a ball screw.

Support and after-sales service

We have four service centers in Japan (CE Center, East Japan, Central Japan, and West Japan). These facilities handle product repair requests and pre-delivery inquiries and provide various services such as troubleshooting consultation, product upgrade proposals, and on-site support.

For overseas after-sales support, contact our Overseas Sales Dept. or your local sales department.

The warranty period is one year after the product is delivered to the location specified by the customer. However, please note that any failure or error resulting from the following causes is not covered by the warranty.

・ The product is handled or used in conditions or an environment other than those mentioned in catalogs, specifications, and manuals.

・ The product is used in excess of durability limits (number of times used, distance, time, etc.), or the failure is due to a reason related to consumables.

・ The failure is due to a reason not related to the product.

・ The product is used in any way not originally intended.

・ The product is modified or repaired by a third party.

・ The failure is due to a reason not foreseeable with the technologies available at the time of shipment.

・ The failure is due to a reason not attributable to us, including disasters, natural and man-made.

Warranty is limited for repairing the product main unit only. Any damage caused by the fault of the delivered product or lost opportunity on the customer’s side will not be covered.

The sales departments in charge of troubleshooting in the respective areas are as follows.

* The departments are closed on Saturdays, Sundays, and national holidays, as well as during summer holidays and year-end and New Year holidays.

[Overseas]

Contact our Overseas Sales Dept. or your local sales department.

[Japan]

East Japan Service

Covered areas

Hokkaido, Aomori, Iwate, Akita, Miyagi, Yamagata, Fukushima, Gunma, Ibaraki, Tochigi, Saitama, Chiba, Tokyo, Kanagawa, Niigata, Nagano, Yamanashi

Central Japan Service

Covered areas

Aichi, Gifu, Toyama, Ishikawa, Fukui, Mie, Shizuoka

West Japan Service

Covered areas

Shiga, Kyoto, Nara, Osaka, Wakayama, Hyogo, Tottori, Okayama, Shimane, Hiroshima, Yamaguchi, Kagawa, Tokushima, Ehime, Kochi, Fukuoka, Saga, Nagasaki, Oita, Miyazaki, Kumamoto, Kagoshima, Okinawa

End-of-life models and alternative models

See the End-of-life products page. For information about alternative models, contact our sales department directly, or contact us through the Contact page of this website.